Sfaturi și informații despre laser

Blogul Epilog pentru gravare și tăiere cu laser

Top 10 întrebări frecvente privind laserul de la fanii Epilog

Fanii noștri au întrebat, iar noi am răspuns – Iată o privire la 10 dintre cele mai frecvente întrebări pe care le pun fanii noștri, împreună cu răspunsurile experților noștri!

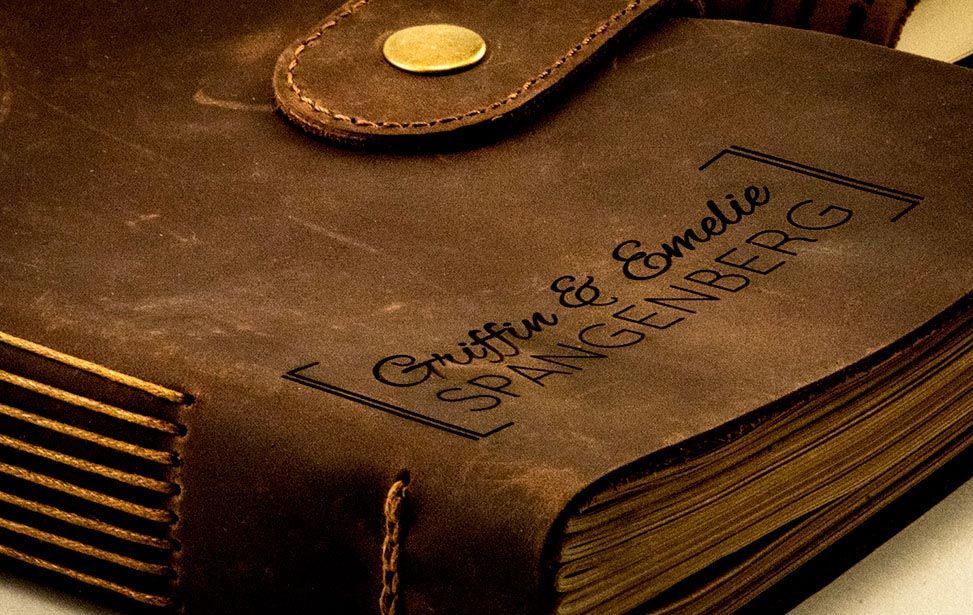

Gravarea cu laser a pielii și gravarea în relief a matrițelor din MDF și acril

O modalitate distractivă de a folosi mașina cu laser pentru a obține un aspect unic pe piele.

Tuburi laser cu CO2 din sticlă vs. metal

De ce sunt fabricate mașinile Epilog Laser cu tuburi metalice răcite cu aer?

5 Cadouri de sărbători pe care le puteți face cu un laser

Impresionează-ți prietenii și familia în acest sezon de vacanță cu aceste proiecte ușor de realizat.

Cum pot laserele ajuta la combaterea contrafacerii

Marcile produse cu laser pot ajuta la securizarea industriilor vulnerabile.

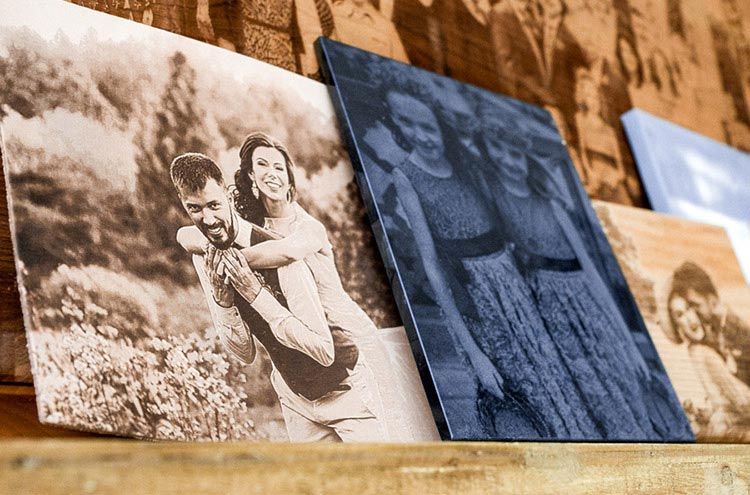

Adaptarea la Schimbările tehnologice în industria Fotografie de nunta - Epilog Laser Blog

Faceți o fotografie de nuntă cu adevărat veșnică cu o mașină Epilog Laser.